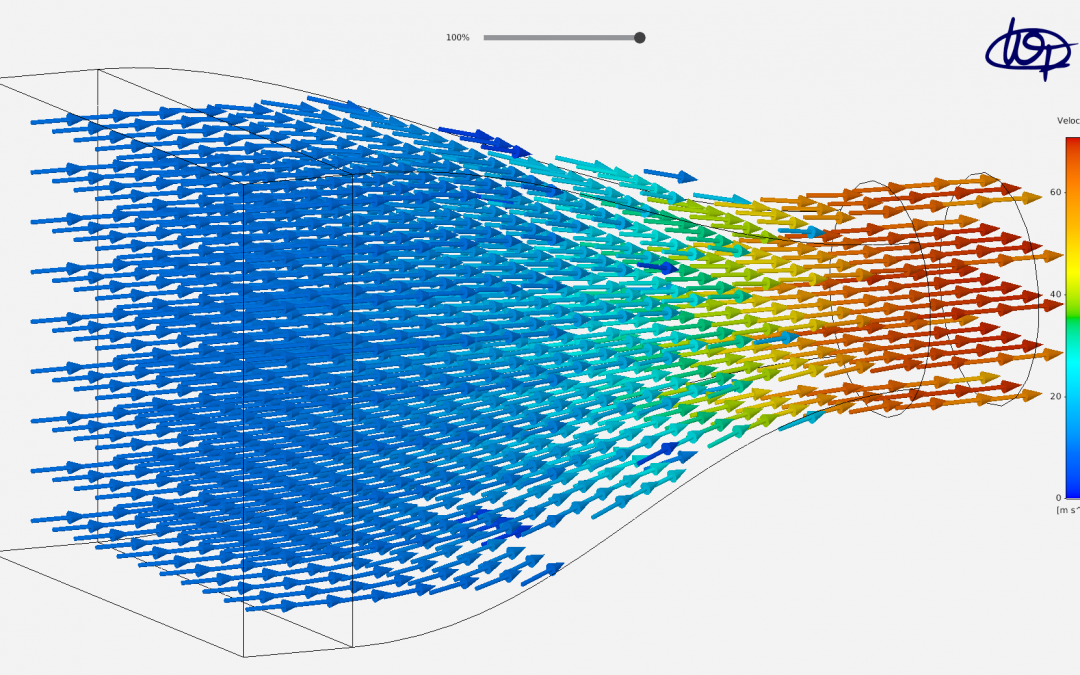

Figure 1: CFD simulation of airflow velocity vectors within a transition duct.

Engineering simulation has rapidly evolved along with increases in computing power and solving techniques. In the right hands, modern simulation is powerful, reliable, and cost-effective. Therefore, engineering simulation will become the norm, rather than the exception, in the near future as more companies in all engineering fields adopt simulation as part of their normal workflow.

Before computers became prevalent in the workplace, many difficult technical computations had to be performed by large mainframe computers such as the one pictured below.

Figure 2: An IBM 704 mainframe from 1964. Source: Wikimedia Commons

Because such machines were cost-prohibitive and difficult to operate, only governments, large corporations, and universities had the capability to properly use computers. The usage of computers in technical calculations, however, combined with exponential increases in computing power over time led to the birth of new fields such as computational fluid dynamics (CFD) and finite element analysis (FEA). Further developments in computing such as the graphical user interface (GUI) helped enable and empower more engineers with advanced modeling capabilities–and helped fields that were once limited to academia with few applications (such as CFD for aerospace technology) proliferate and find their place in many different fields such as HVAC.

Today, the return on investment for adopting simulation technology in HVAC/ACMV is very high. Our firsthand experience has shown us the usefulness and pervasiveness of simulation in many aspects of ACMV design and applications–including but not limited to smoke control pressurization, car park ventilation with jet fans, cooling load calculations, hydronic system feasibility calculations, and airflow visualization in hospital operating rooms (ORs). Simulation capabilities add a high amount of value to technical design at an affordable rate, and allow for accurate design validation in the early stages of a project in order to avoid expensive and time-consuming retrofits in the future.

Although it may take some time and effort to acquire and/or train talent with the right skillset for simulation, it is ultimately worth the cost because there is no substitute to accurate and reliable design analysis in engineering. Simulation is an indispensable tool for the modern engineer to achieve accuracy and reliability in design. Therefore, we recommend further investigation into the possible benefits of engineering simulation for you and your project.

Shwe Myat Myo Oo (ေရြႊျမတ္မ်ိဳးဦး)

Lead Engineer, Technical Development Division

B.S. 2016, Mechanical Engineering

Georgia Institute of Technology

Associate Member ASHRAE

Member ASME